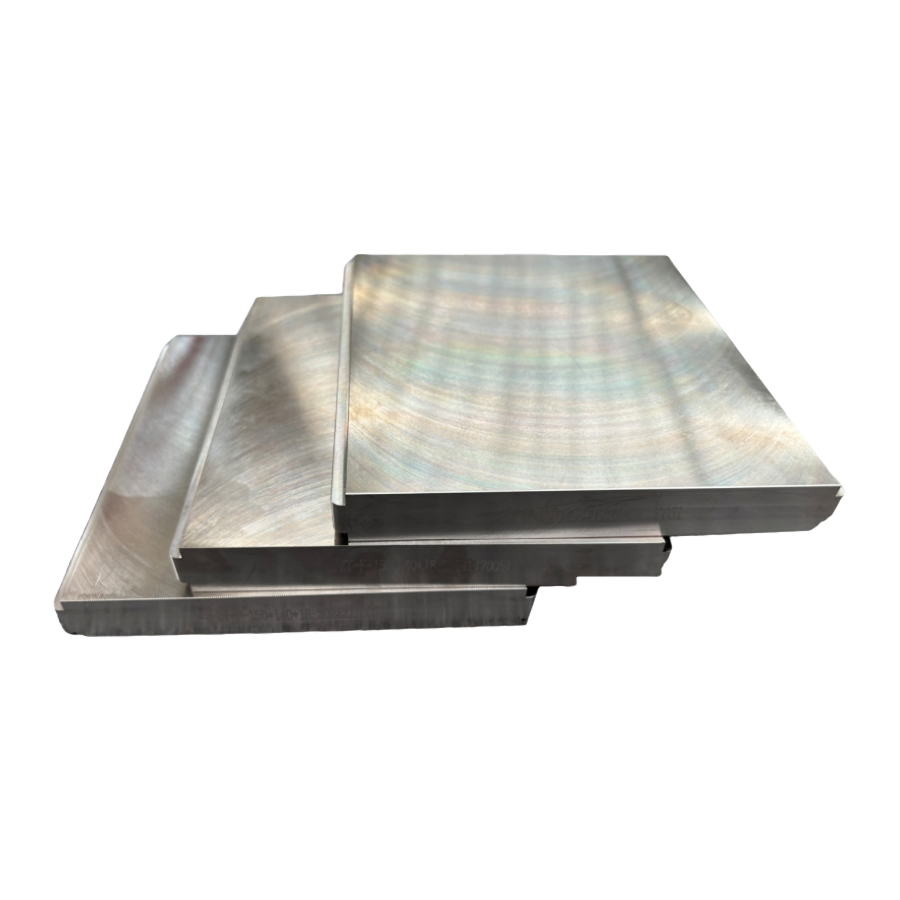

Rubber Diamond Grinding

Engineered for high-efficiency polishing of dental prostheses, the Rubber Diamond Grinding integrates advanced materials and precision engineering to deliver dry-processing solutions for zirconia, precious metal alloys, ceramics, and resin workpieces. Its medical-grade silicone matrix is uniformly embedded with 20–50 μm diamond particles, enabling three-layer grinding (coarse grinding, contour refinement, and mirror polishing) without water cooling. The temperature rise is controlled at ≤3°C (at 20,000 RPM), eliminating thermal damage risks to restorations.

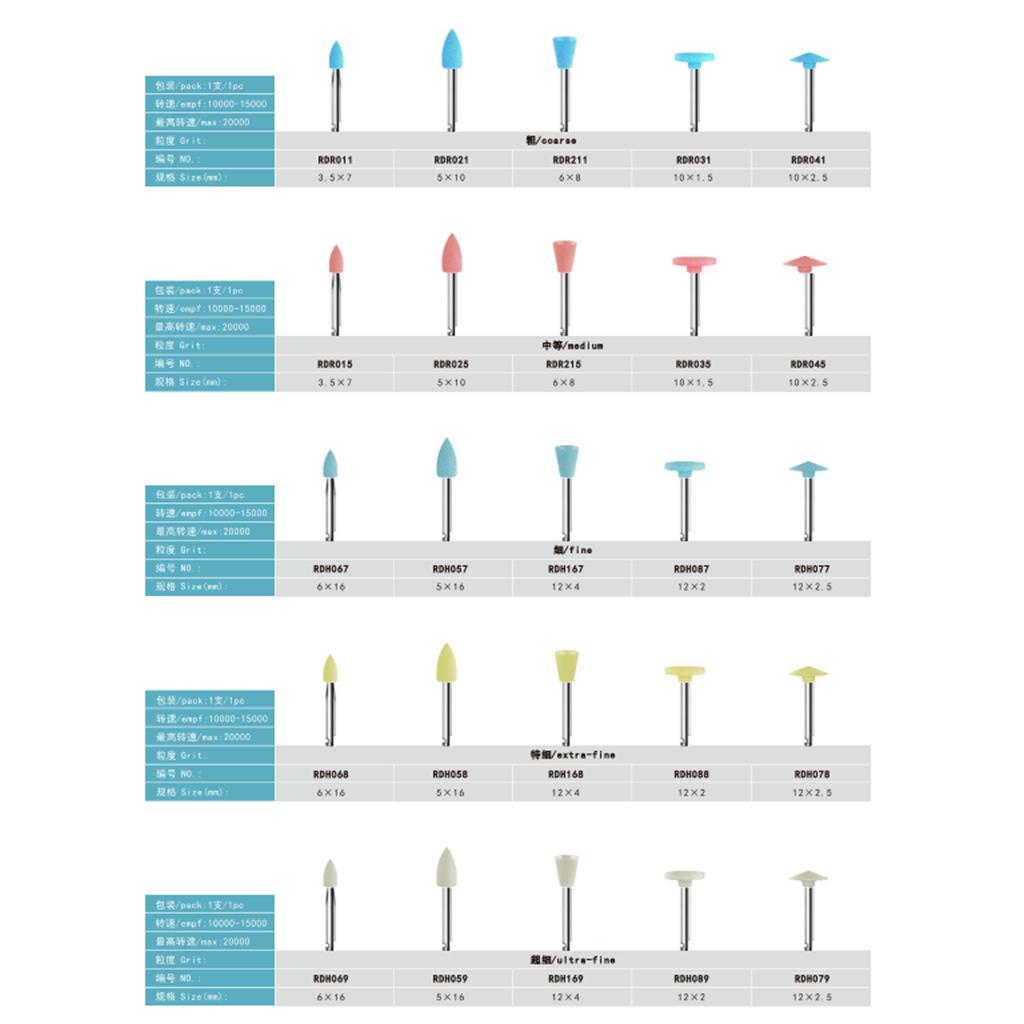

Specification

| Parameter | Details |

| Grit | very coarse、coarse、medium、extra-fine、ultra-fine |

| Speed Range | 10,000–15,000 RPM (maximum for 20,000 RPM) |

| Material Safety | USP Class VI biocompatible rubber (FDA 21 CFR 872.4200) |

| Thermal Stability | Dry operation certified (max 120°C) |

| Durability | 50+ restorations per bur (lab-tested on zirconia) |

| Packaging | Sterile single-unit plastic case |

Advantage

1. Advanced Dry-Grinding Technology

- Waterless Operation: Proprietary heat dissipation channels reduce friction-induced temperature rise to ≤3°C at 20,000 RPM, enabling safe dry processing of zirconia/ceramics.

- Multi-Layer Diamond Matrix:

- 50 μm Coarse Layer: Achieves 0.2–0.3 mm/s material removal rate (lab-tested on zirconia blocks).

- 20 μm Medium Layer: Refines contours with Ra 0.5 μm surface roughness.

- 5 μm Polish Layer: Delivers mirror finishes (Ra ≤0.1 μm) in a single tool.

2. Enhanced Durability & Material Innovation

- Synthetic Diamond Reinforcement: Grade 6 industrial diamonds (1100GPa hardness) ensure 3x lifespan vs. resin-bonded alternatives (60+ restorations/bur) .

- Uniform Abrasive Distribution: Electrostatic bonding technology prevents diamond shedding (<0.01% loss after 50 cycles) .

3. Workflow Optimization

- Time Efficiency: Completes crown adjustments in 2–3 minutes (vs. 5–8 mins for water-cooled systems) .

- Ergonomic Compatibility: 45° angled head design facilitates access to posterior implant prostheses (compatible with NSK/Bien Air handpieces) .

4. Cost-Effective Performance

- Reduced Consumable Costs: 60% lower replacement frequency compared to conventional burs.

- Multi-Material Adaptability: Single tool handles zirconia crowns, lithium disilicate margins, and PMMA dentures, reducing inventory needs.

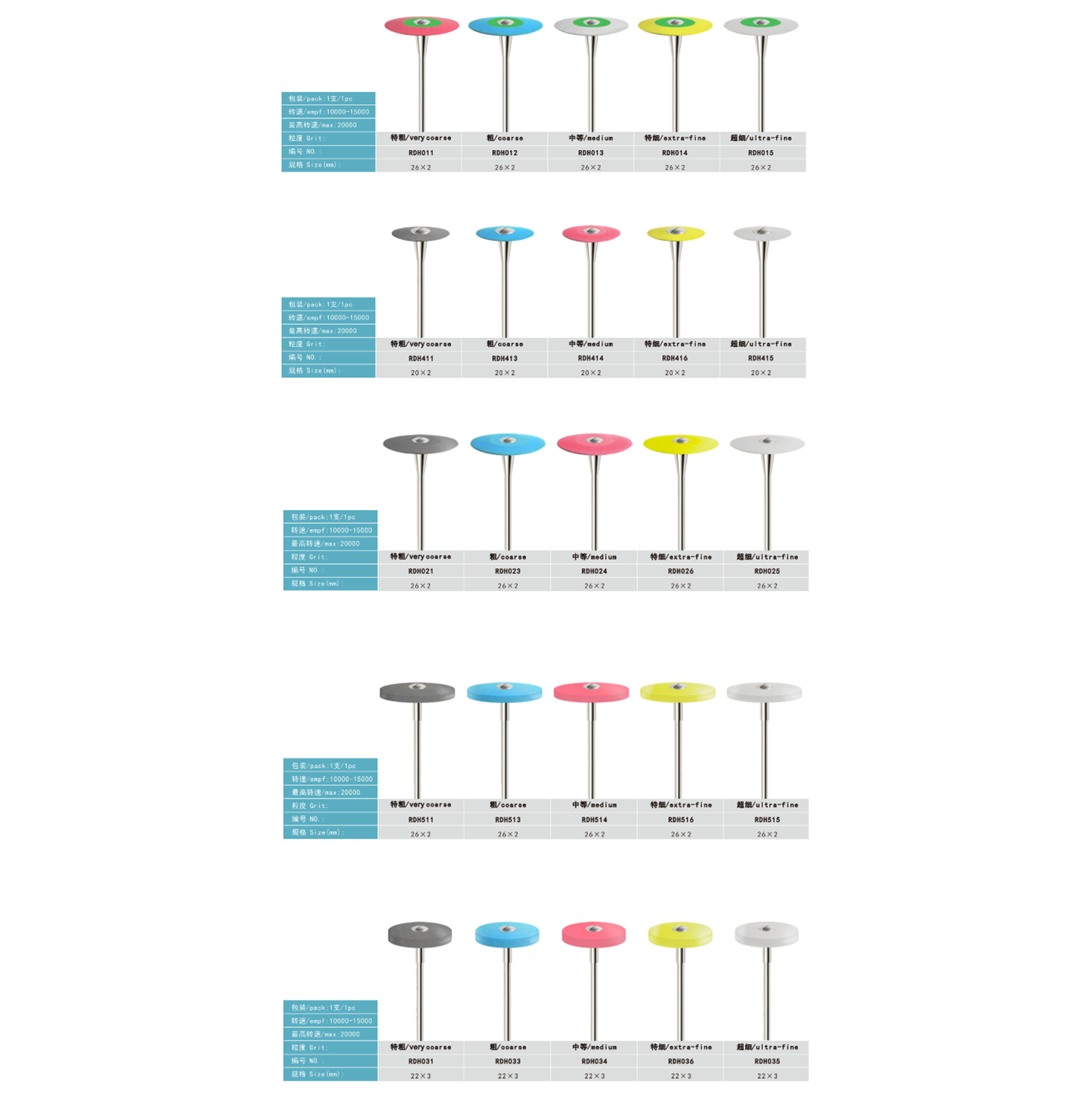

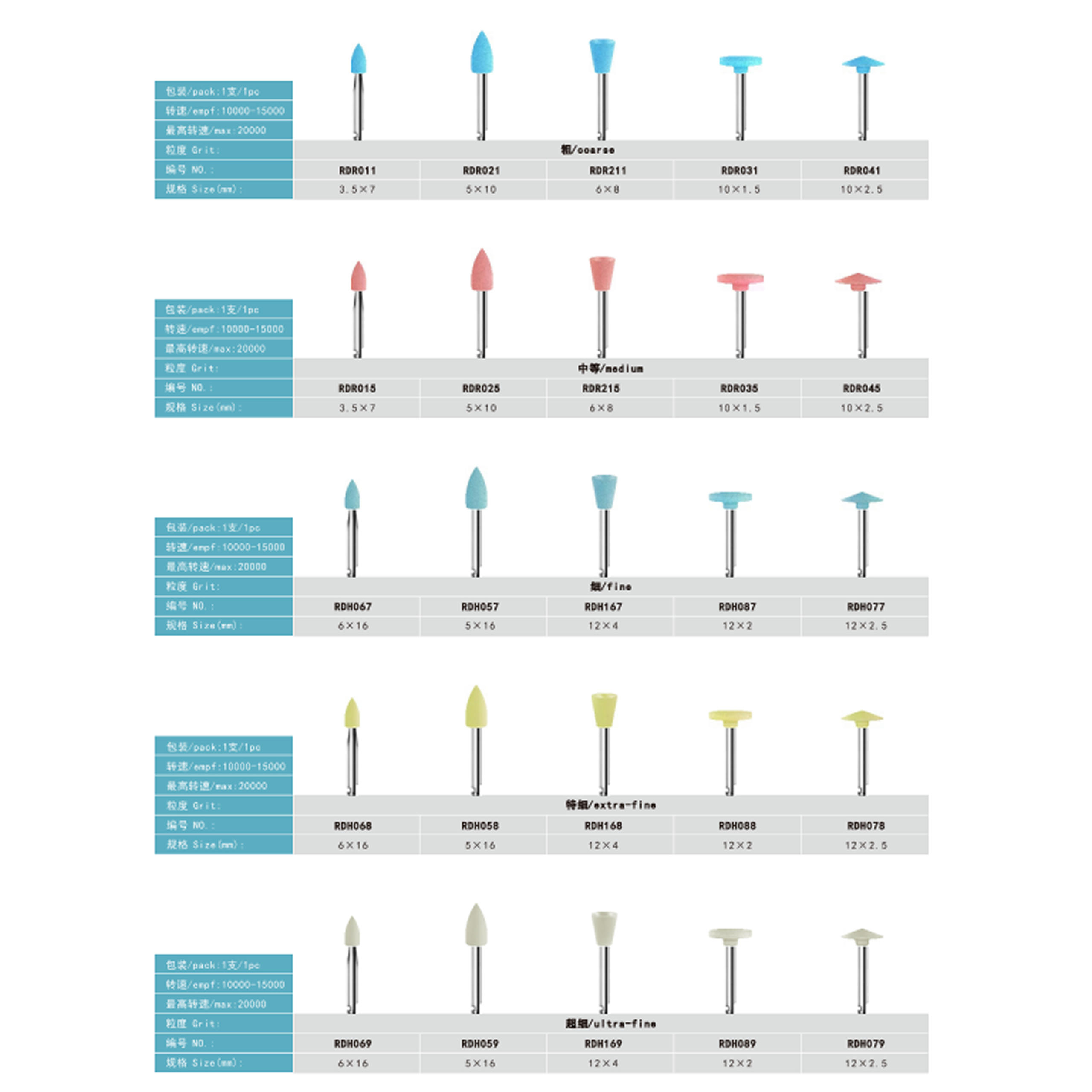

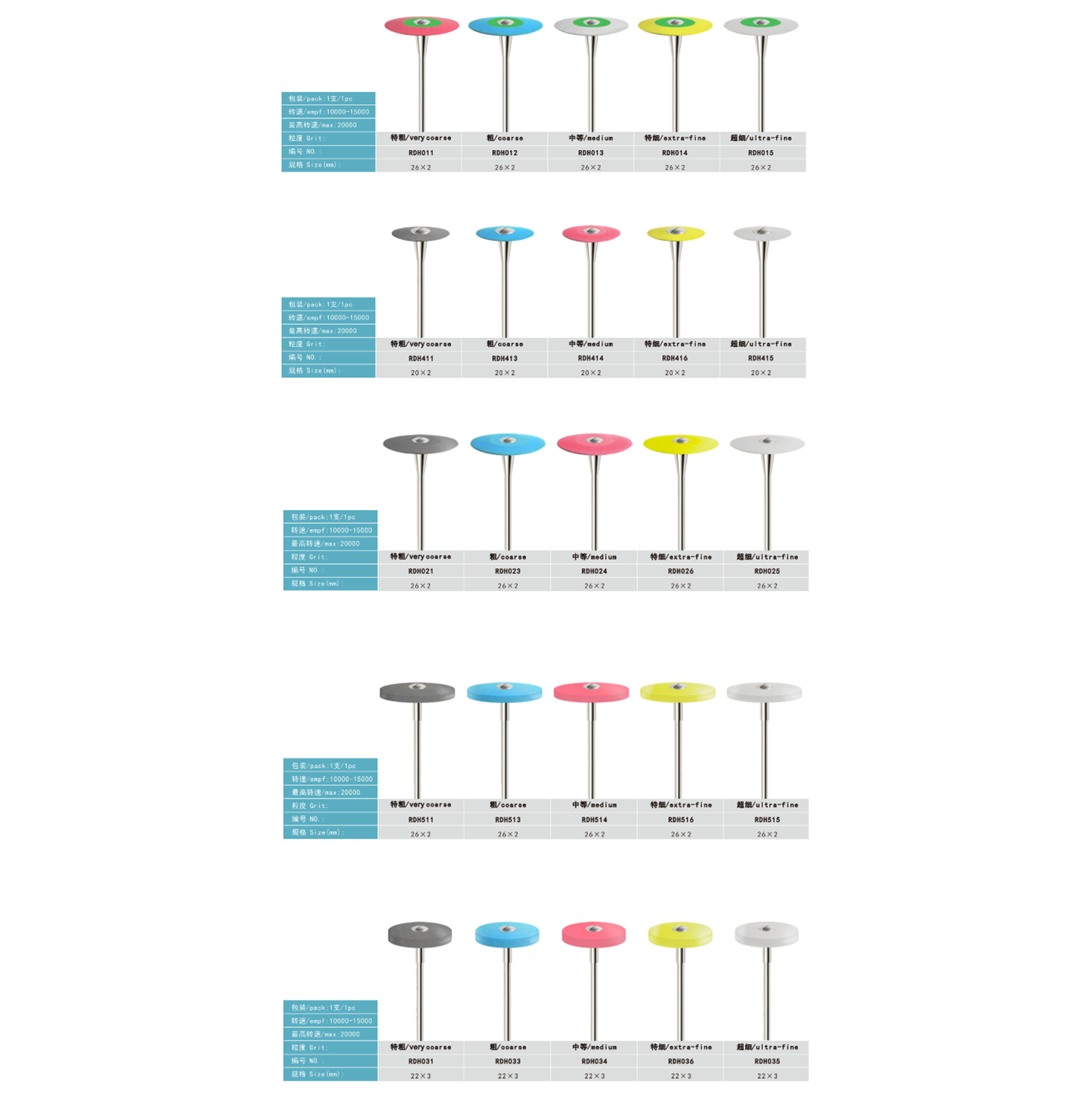

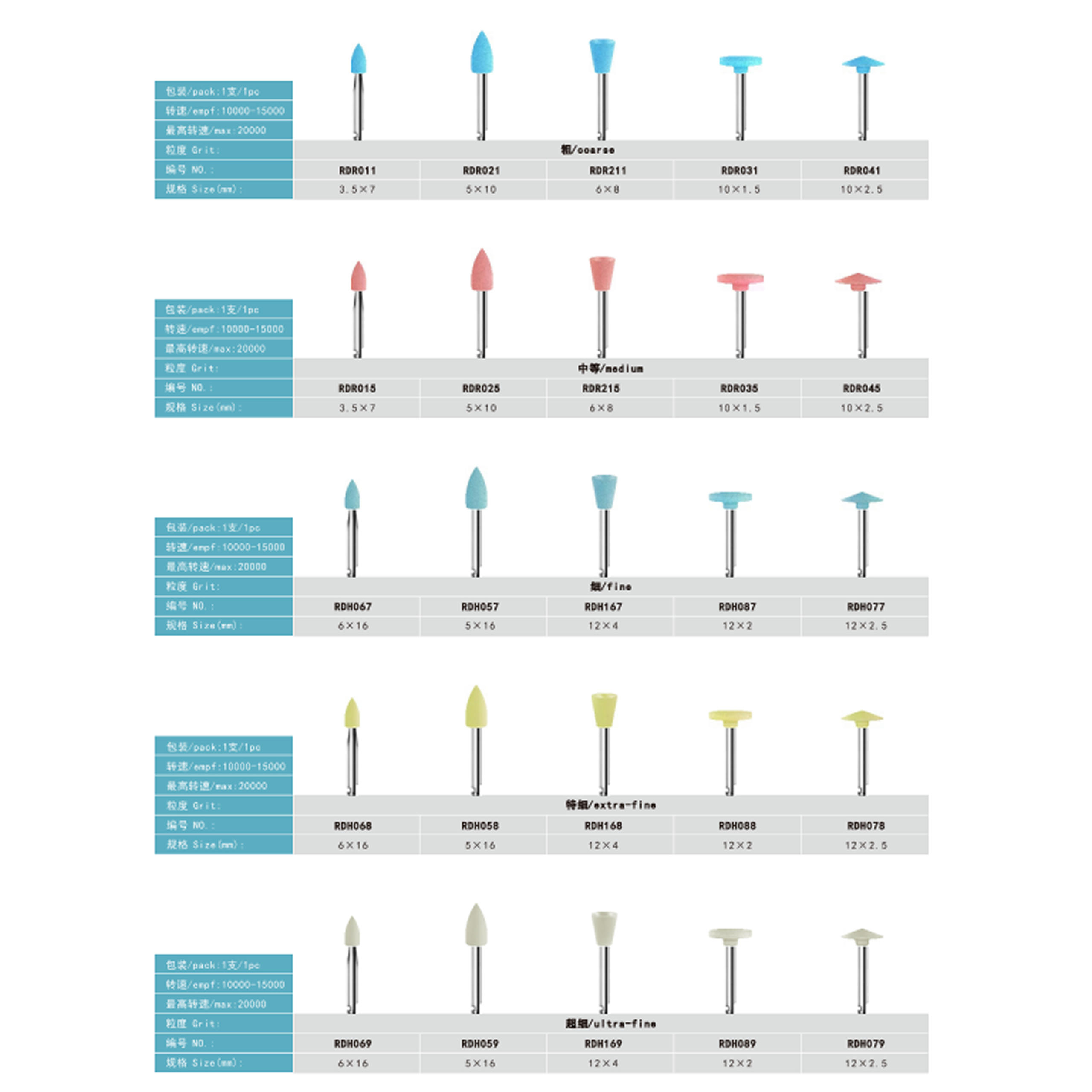

Product Diagram

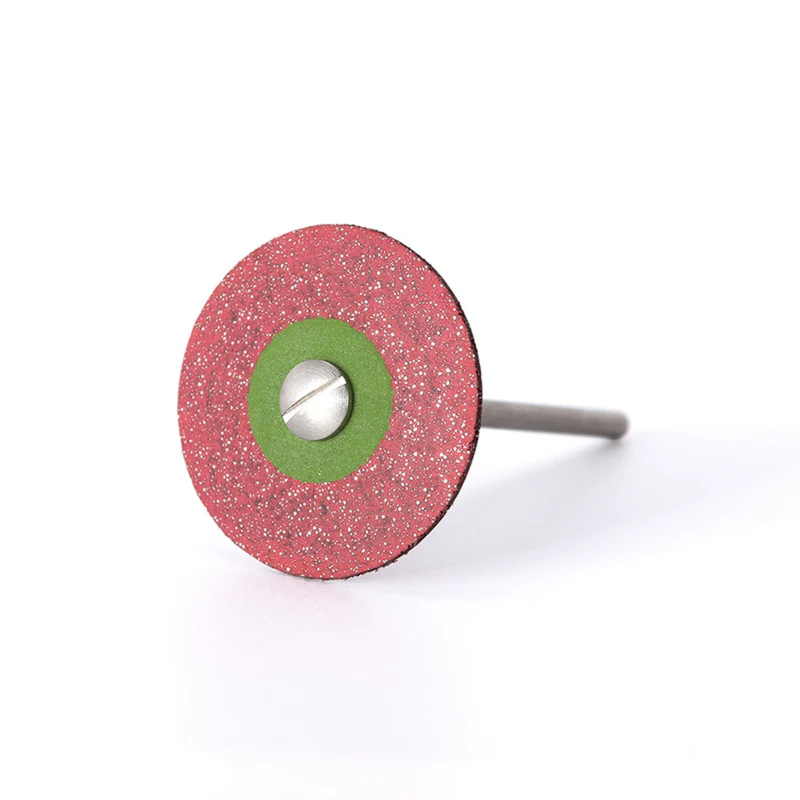

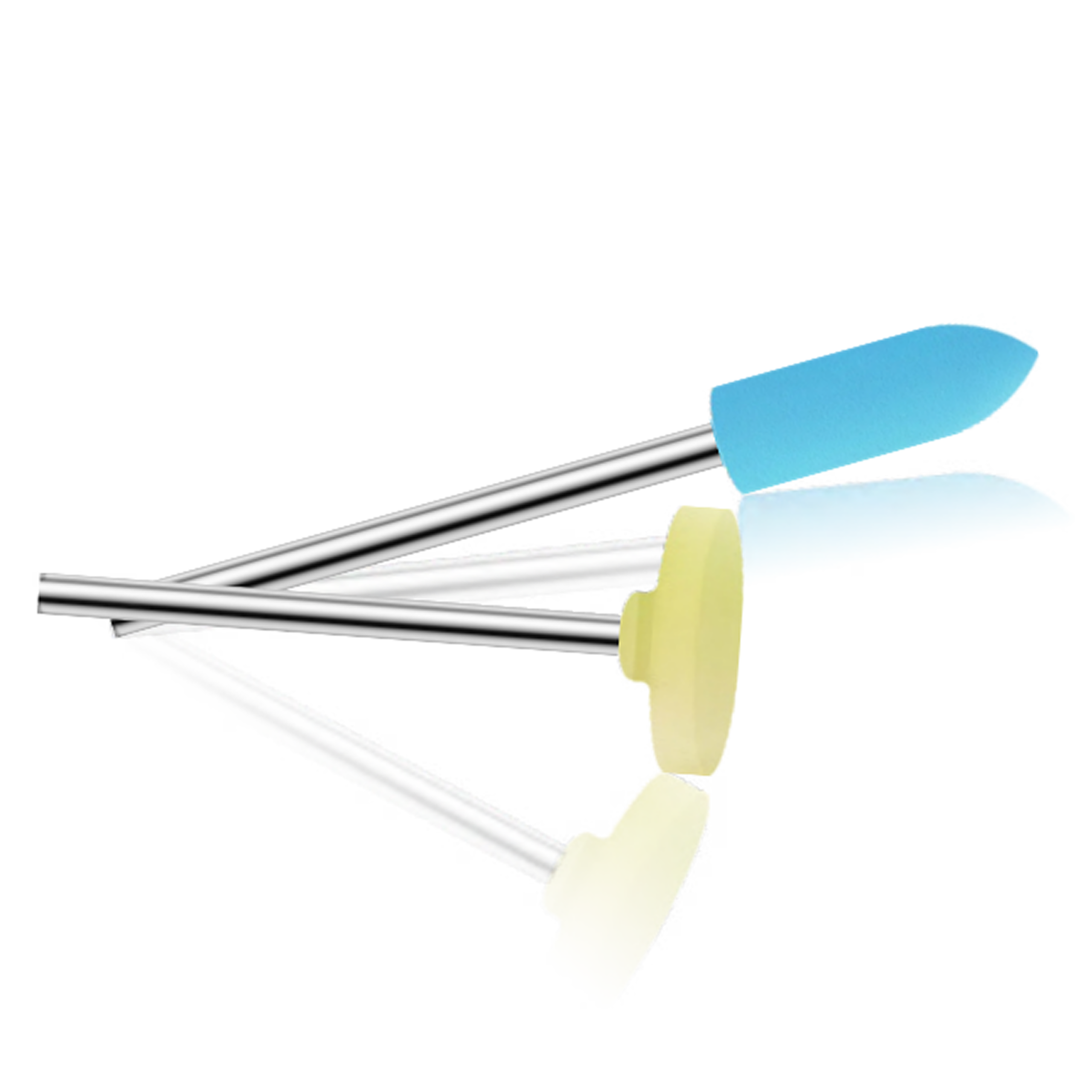

For smoothing and polishing zirconia, precious metal, alloy and porcelain workpiece, soft and flexible, high-shine polishing without paste, high quality and efficiency.

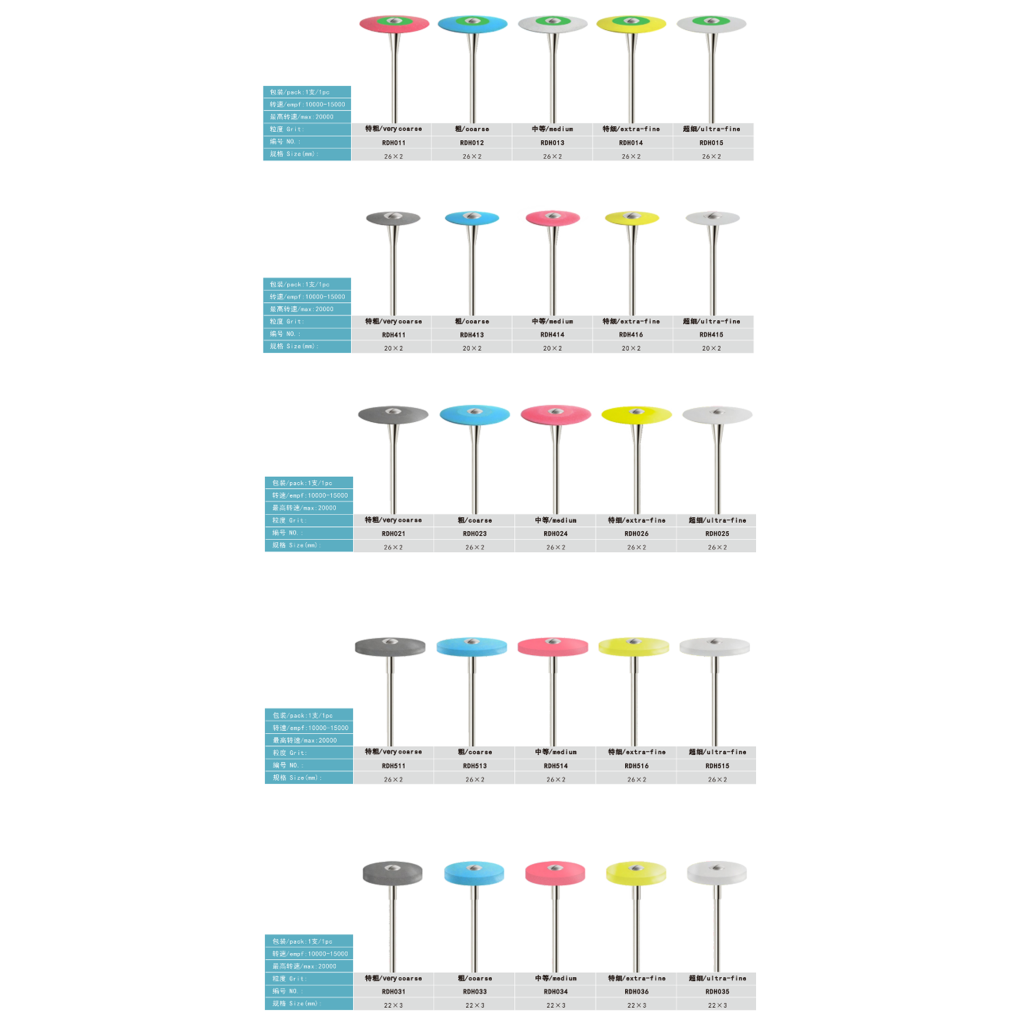

Specification: includes item no., pack, grit, empf, max empf, size.

High Bright Polishing Series:

For smoothing and polishing zirconia, precious metal, alloy and porcelain workpiece, soft and flexible, high-shine polishing without paste, high quality and efficiency.