Procelain Powder

The ERADENT Porcelain System is a comprehensive dental ceramics system designed to provide dental professionals with a range of high-quality materials and techniques for crafting aesthetic and functional dental restorations.

Scope of Application

This product is used for coating on a metal base crown. After forming into a crown shape and sintering, it forms a restoration where the metal base crown is combined with this product.

Specification

| Sintering times | Thermal Expansion Coefficient | Glass Transition Temperature | |

| Powder Opaque | 13.0×10-6K-1 | 13.0×10-6K-1 | 500℃ |

| Body | 13.0×10-6K-1 | 13.0×10-6K-1 | 515℃ |

| Ename | 13.0×10-6K-1 | 13.0×10-6K-1 | 530℃ |

Firing chart

Product FAQ & Manual

[Operation and Usage Method]

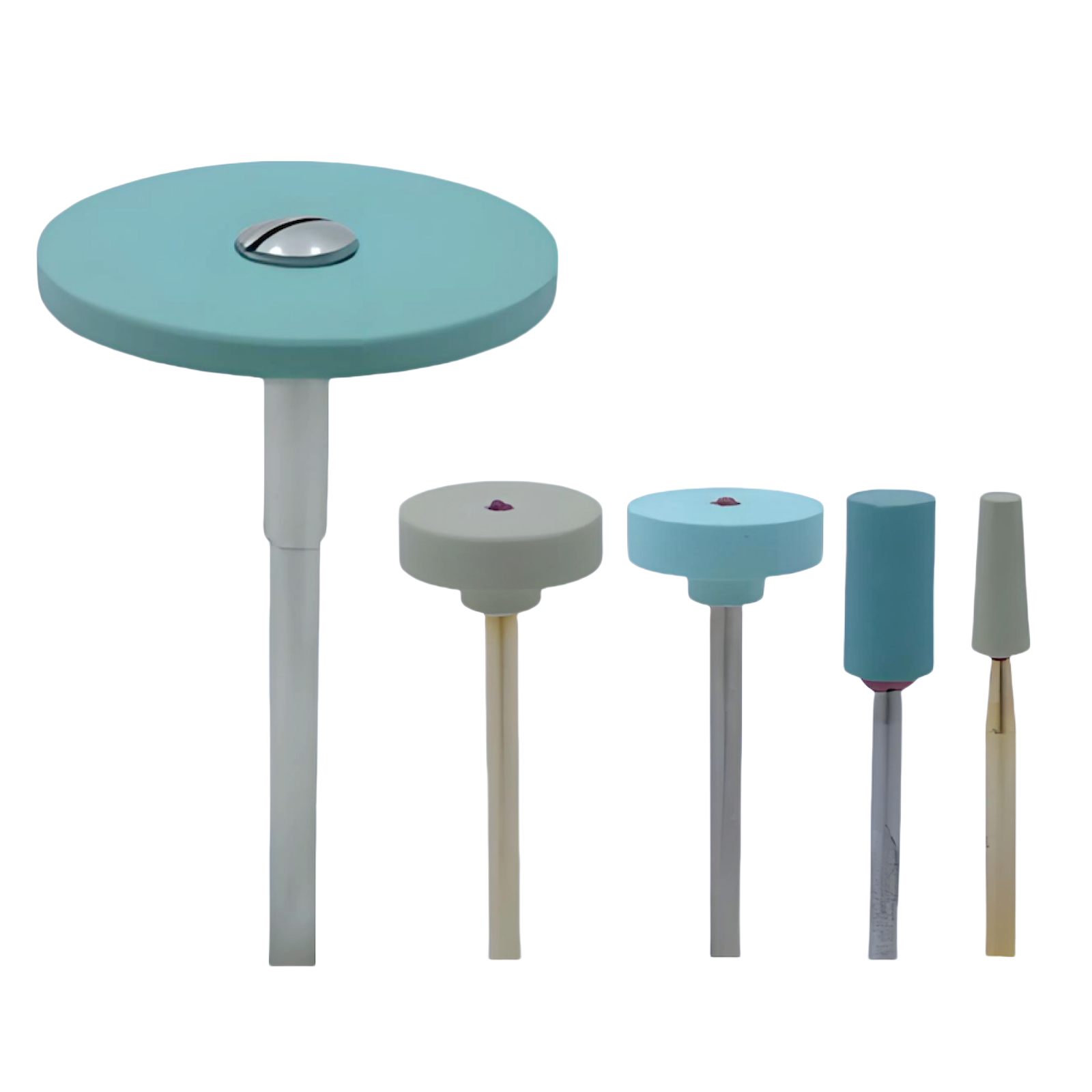

- After making morphological adjustments to the metal base crown, clean and pre-oxidize. After confirming the fit of the metal base crown, use tungsten steel aluminum oxide burs for grinding and trimming, adjusting the thickness to 0.3mm. After the shape adjustment is complete, clean the metal base crown in an ultrasonic cleaner for about 10 minutes, then follow the manufacturer’s instructions for pre-oxidation treatment.

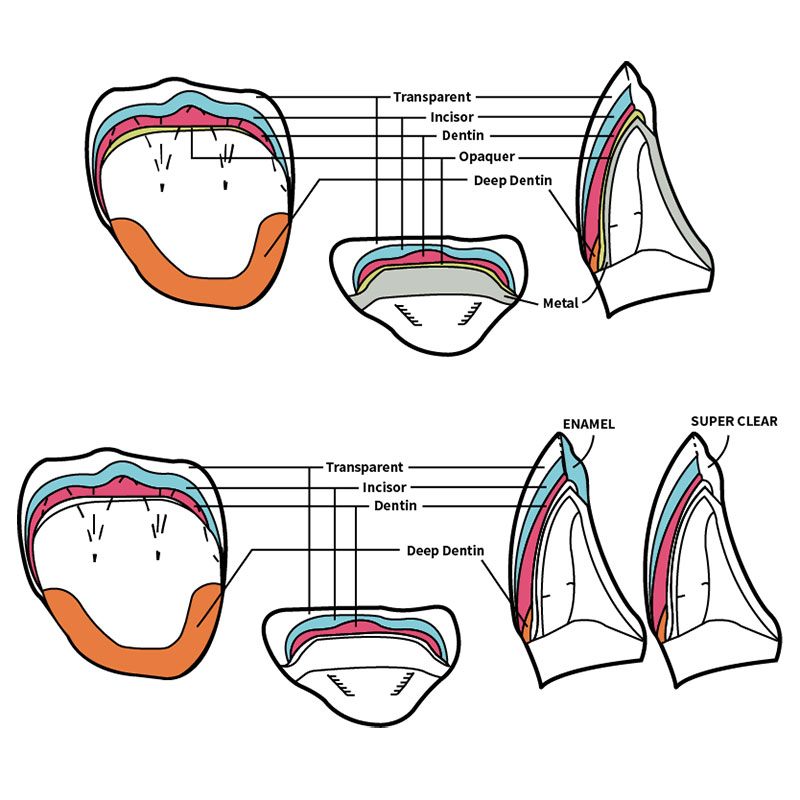

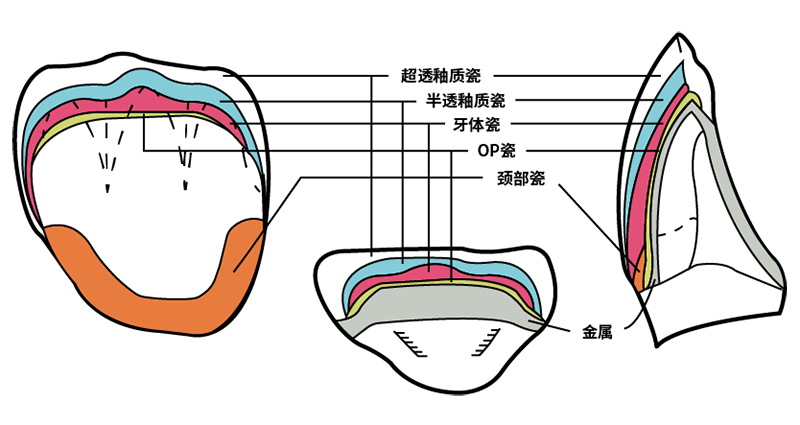

- Application/Sintering of Opaquing (Opaue) with NEUTRAL:

Mix the special liquid (Opaque Liquid) with the powder opaque and apply a thin layer evenly on the surface of the metal base crown. - Proceed with the sintering program as recorded in the instructions.

- Application/Sintering of Opaque with Colored System:

Apply the second layer of powder opaque, with a total thickness of 0.2mm, and sinter to reproduce the basic color of the target tone. After sintering, the surface should have an eggshell-like luster. - Application of Dentin Porcelain (Body):

Use dentin to construct the shape of the crown. Mix and apply dentin porcelain and cervical porcelain (Cervical) as needed at the cervical area. The thickness should be more than 0.5mm. - Application of Enamel Porcelain (Enamel):

Apply enamel porcelain at the incisal third of the cutting edge. The amount of enamel porcelain applied should be based on replacing the amount removed by the back-cutting process, being careful to avoid excessive application of enamel porcelain. The thickness should be 0.2mm. - Application of Translucent Porcelain (Transucent):

Apply translucent porcelain, which should be about 10% larger than the target crown shape to compensate for shrinkage during sintering. - Sintering:

The surface of the sintered crown should have a slight luster, indicating the appropriate sintering state. - Shape Modification, Glazing, and Completion:

Make shape modifications and clean. After cleaning, perform glazing sintering.

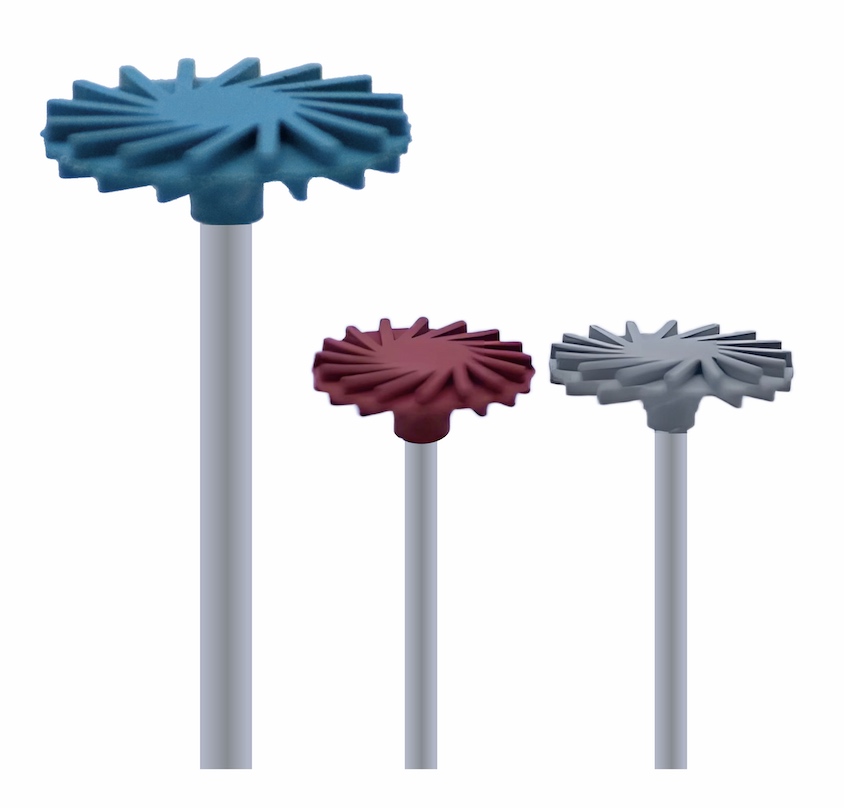

Gallery

Get Free Quote of Procelain Powder

Related News

[product_related_posts]