Glass ceramic lithium disilicate CAD

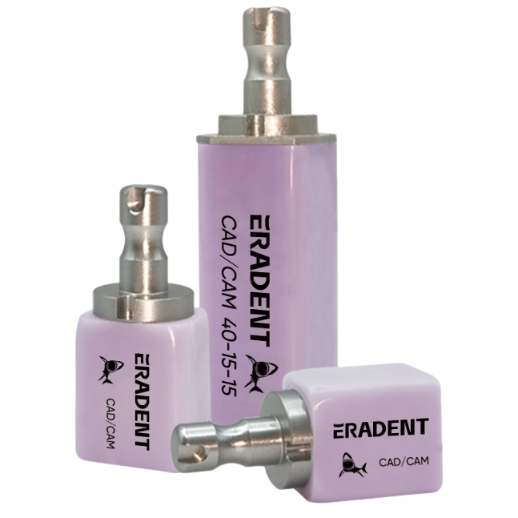

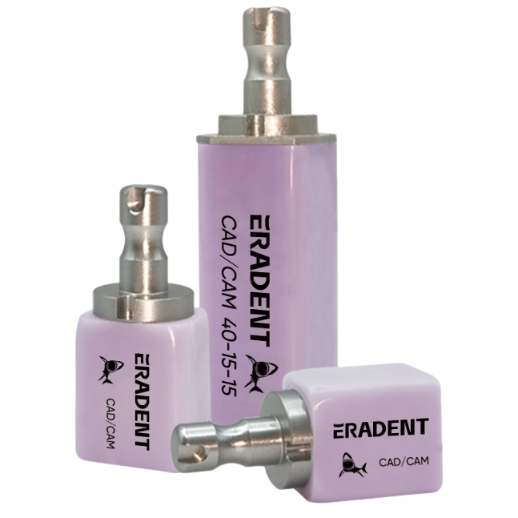

ERADENT glass ceramic blocks, made from excellent raw materials, apply the fine craftmanship, featuring the simple and fast crystallization, perfect flexural strength and processibility as well as outstanding aesthetic effect. It has become the world’s bestselling CAD&CAM chairside dental materials.

Product advantage

- Natural and vivid color, excellent aesthetic effect, excellent translucency through appropriate light scattering, vivid milky white with natural fluorescence.

- Moderate strength, strength ≥400MPa after complete crystallization, and low abrasion to jaw teeth.

- Suitable for veneer, inlay and crown restoration.

- Short processing time, suitable for chair-side dental restoration, and short waiting time for patients.

- Excellent bonding performance, low probability of patients falling off their teeth.

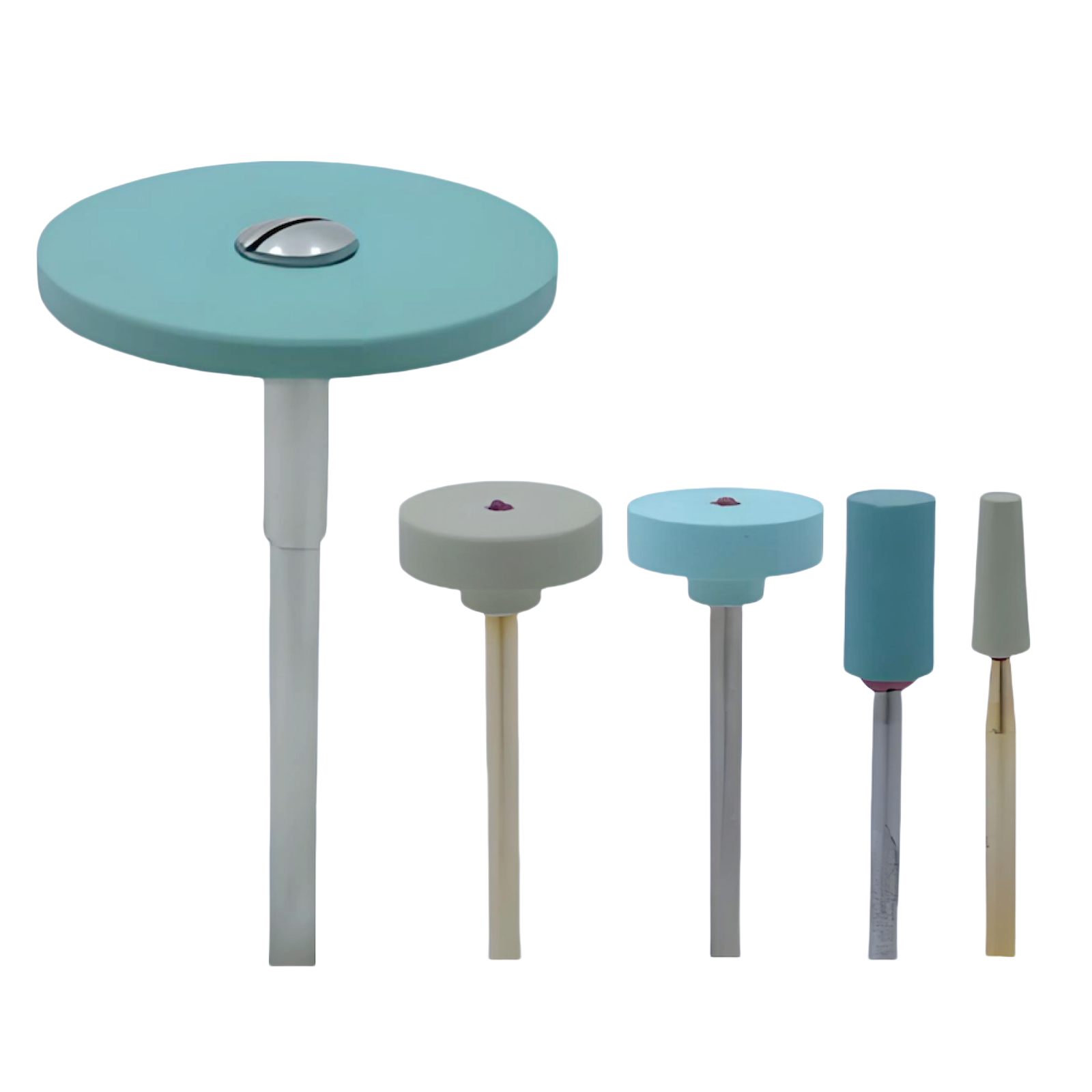

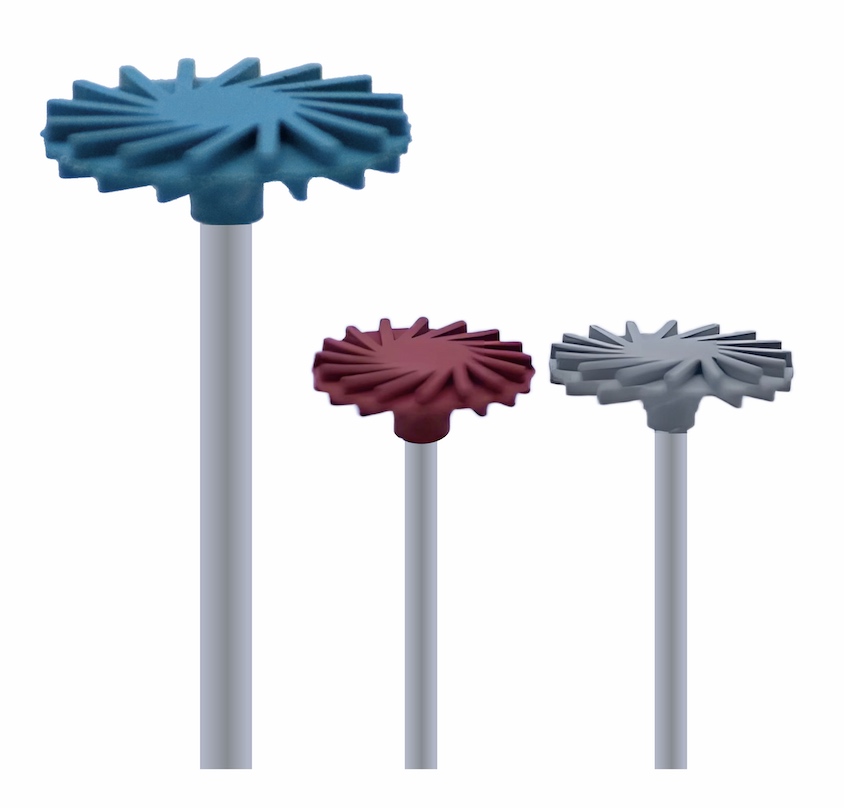

- Easy to polish, reduce the wear of grinding head. The chip incidence is lower and the edge stability is high. Proper hardness and bending strength (not crystallized) ensure the long life of milling needles.

- With the simple and easy operation, patients could experience a same day restoration.

- Rapid crystallization, the first choice for immediate restorations.

- High strength, suitable for various cases.

- High translucency, demonstrating the natural color of the teeth.

Recommend indication

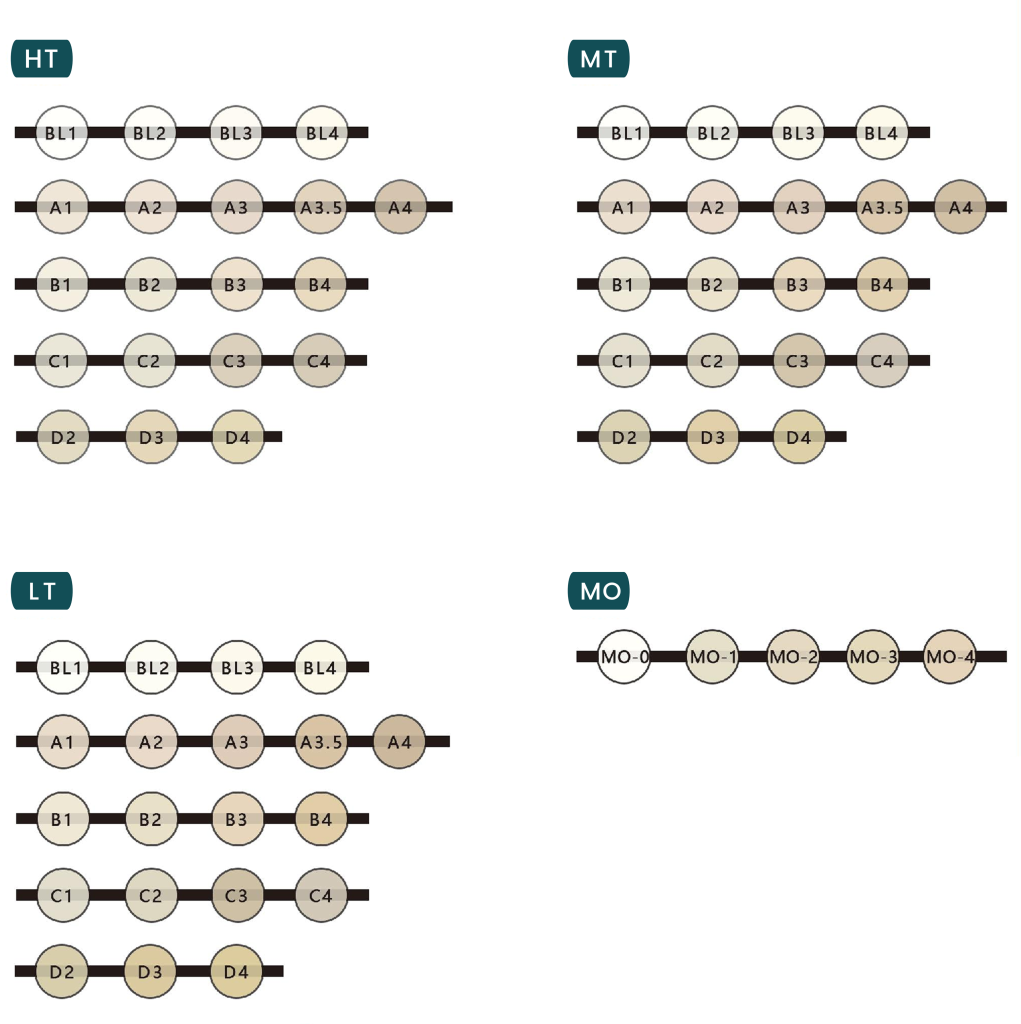

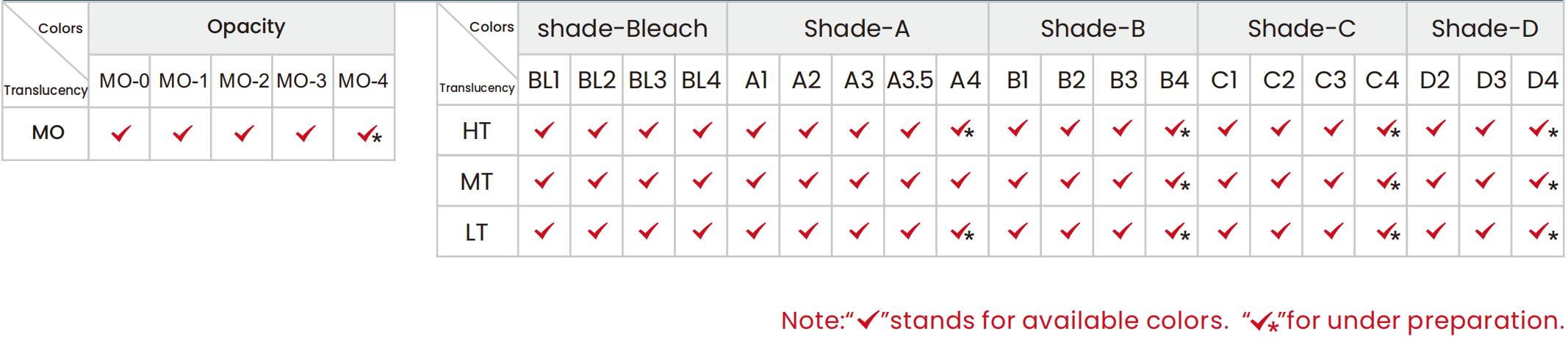

Transparency

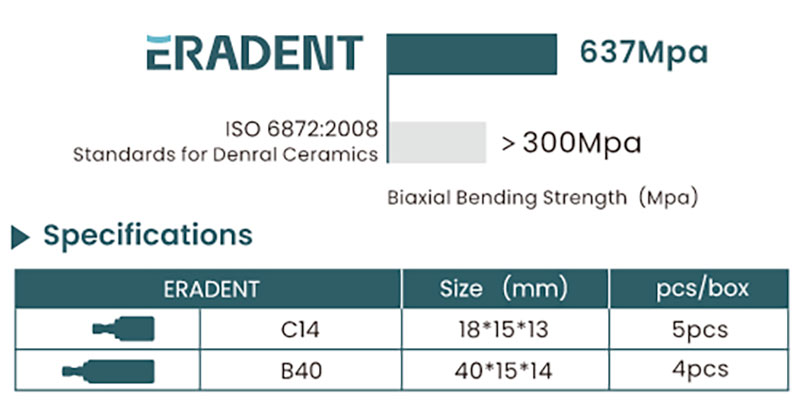

Specifications

Available shades

Technical Data

| Composition | SiO₂ 61%-71%, Li₂O 11%-17%, ZrO₂ 1%-5%, other oxides 6%-30% |

| Density(g/cm³) | 2.4-2.7 |

| Vickers hardness(MPa) | 5400±400 |

| Fracture toughness(Mpa·m¹⁄²) | 2.55 |

| Coefficient of ehermal expansion(10⁻⁶K⁻¹) | 9.8±0.5 |

| Crystallization Temp(℃) | 840-850 |

| Chemical solubility(µg/cm⁻²) | 30.3 |

| Radioactivity(Bq/g) | <0.019 |

| Cytotoxicity test | Cytotoxicity level 0 |

| Short-term systemic toxicity study (oral route) | No systemic toxicity |

| Sensitization test | Non-allergenic |

| Hemolysis test | Hemolysis rate < 5% |

| Ames test | Mutagenesis negative |

| Oral mucosal irritation test | No oral mucosal irritation |

| Subchronic systemic toxicity test | No subchronic systemic toxicity |

Crystallization Curve

| One-stage crystallization procedure | starting temperature | Drying time | heating rate | maintain temperature | hold time | Opening temperature | vacuum begins | Vacuum ends |

| 400℃ | 30s | 40°C/min | 840°C | 7 min | 700℃ | 550°C | 840°C |

| Two-stage crystallization procedure(recommended) | starting temperature | Drying time | Heating Time | Heating Time | Hold time | Hold Rate | Holding Temperature | Residence Time | Furnace-opening Temperature | Vacuum-on | Vacuum -off |

| 400℃ | 6min | 60℃/min | 820℃ | 10s | 30℃/min | 840℃ | 7min | 700℃ | 550/820℃ | 820/840℃ |

Gallery

Get Free Quote of ERA.Lithium disilicate.CAD

Related News

[product_related_posts]