Glaze & Stain Kit

Glaze & Stain Kit is a Simplified and Aesthetically Superior Solution for Zirconia Restorations. It’s a complete solution that includes a glaze, 3D natural shade, and essential liquids for dilution and refreshment, ensuring that every aspect of the staining process is covered.

Product advantage

- Comprehensive Set: The set includes four main ABCD shades, 18 special effect colors, a glaze, a 3D natural shade, and both diluting and refreshing liquids.

- Ready-to-Use: The paste does not require the mixing of powder and liquid before use, which is convenient and time-saving.

- Integrated Glaze Ingredients: Each bottle of paste in the set contains ingredients for glaze, eliminating the need for a separate glazing application.

- Single Staining Process: The product aims to achieve the ideal effect through a single staining process.

- Customizable Shading: The shades from each paste can be freely matched to achieve a satisfactory effect on the crown’s shade and can be used directly after being mixed evenly.

Specification

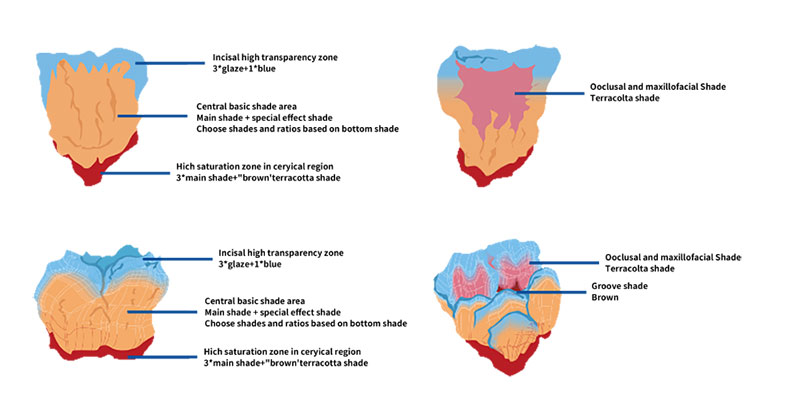

Usage Method: as the figure shown

Storage Method: The product should be stored in dry conditions with an optimal temperature range of 12°C to 38°C. After use, the bottle cap should be tightly sealed, and the product should be kept in a hygienic environment.

Product FAQ & Manual

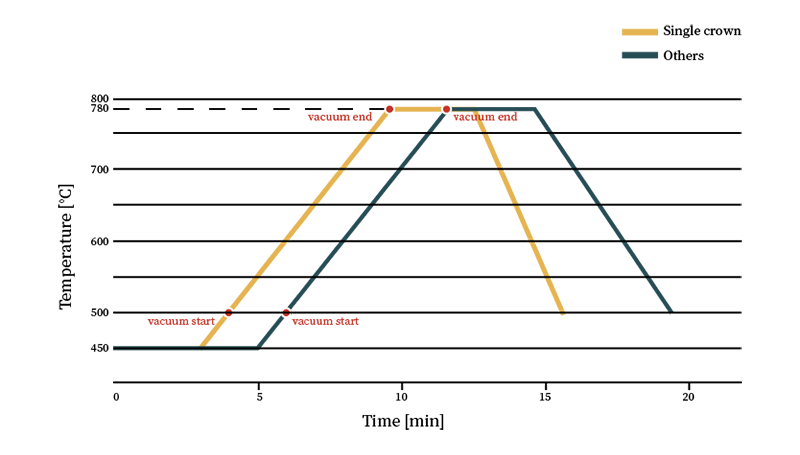

Standard Paste Sintering Curve

| First sintering | Secondary sintering | Single crown laze sintering | Zirconia bridge intering(4-7 units) | Zirconia brdge sintering (8 units and above ) | |

| Hold time | 450 | 450 | 450 | 450 | 450 |

| rying time | 5 | 5 | 3 | 5 | 5 |

| Heating rate | 50 | 50 | 50 | 50 | 50 |

| Vacuum start temperature | 500 | 500 | 500 | 500 | 500 |

| vacuum end temperature | 780 | 780 | 780 | 780 | 780 |

| Sintering temperature | 780 | 780 | 780 | 780 | 780 |

| Hold time | 3 | 3 | 3 | 3 | 3 |

| low cooling | 5 | 5 | 5 | 5 | 5 |

| Take out temperature | 500 | 500 | 500 | 500 | 500 |

Gallery

Related News

[product_related_posts]